|

|

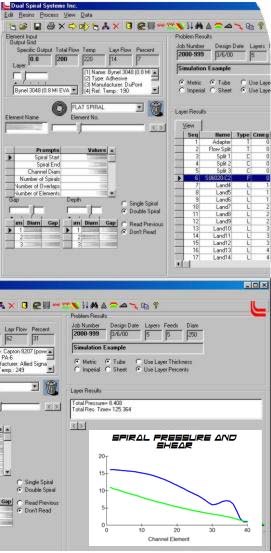

Dual Spiral Systems Design Software

Our approach to designing high performance extrusion equipment is by using computer software in conjunction with knowledge and experience. Comparison with actual system performance allowed us to check the simulation for accuracy.

We use a combination of in-house developed and commercially available plastics engineering software allowing us to simulate any extrusion system regardless of geometry, polymer materials used and process specifications. As part of our design process, all our die and feed screw designs are put through a rigorous computational analysis in order ensure that the equipment we supply is optimized to provide maximum efficiency and profitability. The software is not meant as a replacement for the in depth experience gained from designing numerous extrusion systems.

Included in every die we manufacture is our Die Signature simulation software, given to our customers, to allow them to see how changing variables on their extrusion line will affect the actual line in terms of pressure, residence time and many other variables. This software helps in new product research and development.

|

|  |